Troubleshooting suitable for Sundyne Pumps: Fast Solutions for Complex Problems

- Sammler CS

- Apr 29, 2025

- 3 min read

Updated: Apr 30, 2025

High-performance pumps are the heart of many industrial processes, especially in refineries operating in the downstream sector processing crude oil. These pumps, such as the Sundyne LMV series, operate under extreme conditions and are essential for continuous production. When one of these pumps fails, the impact can be significant. But what exactly happens when a pump goes down, and why is rapid troubleshooting so crucial?

The Most Common Problems with High-Performance Pumps

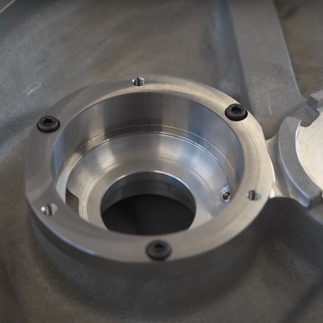

High-performance pumps, such as the LMV-311 or LMV-322, are highly complex machines that operate under high pressure and continuous load. Potential issues often arise at the bearings, shaft seals, or due to mechanical wear. These defects can result from heavy loads in combination with inadequate service. When such a pump fails in a facility, such as a refinery, it often does not mean the entire plant shuts down, but a critical production unit is disabled. This may lead to reduced oil processing capacity, which significantly restricts productivity.

Even short downtimes can quickly result in significant losses, as the refinery process is tightly scheduled, and any delay can cause subsequent failures. A shutdown of just a few hours can already cause enormous financial losses, further emphasizing the need for rapid and effective troubleshooting.

A Practical Example: Fast Response Makes the Difference

Let’s take the real-life example of a refinery in India that specializes in crude oil processing. One morning, a high-performance pump fails. The reason: a worn ball bearing liner in the gearbox housing causes excessive vibrations within the gearbox. Before even greater damage occurs, the plant manager decides to shut down the pump to avoid damaging the remaining components due to the increased load. Despite having a twin pump in place, the risk of a total plant failure increases, with potentially severe consequences. If the redundant pump fails, everything comes to a halt.

Without a prompt repair of the primary pump, the risk of total failure increases day by day. As a result, the refinery faces a potentially prolonged production interruption, which could lead to substantial losses.

The team from Maverick Dynamics, the official India representative of Sammler CS, is immediately informed and arrives on-site with the troubleshooting team in no time. Thanks to Sammler CS’s global presence with specialist and well-equipped workshops equipped with state-of-the-art tools near industrial hotspots, a rapid response is possible worldwide. Just one day after the initial call, the experts are on-site, inspecting the facility and diagnosing the problem. However, successful troubleshooting depends not only on quick response times, but other factors are just as important.

The Availability of Spare Parts: A Critical Factor

One of the biggest pain points in repairing high-performance pumps is the availability of the correct spare parts. Often, the required components are not immediately available, which significantly delays repairs. With Sammler CS, this is different. Thanks to a comprehensive inventory of over 500 different components—including all standard spare parts suitable for Sundyne and Sunflo pumps—defective parts can often be replaced directly on-site. This means there are no long waiting times, and the pump can be brought back into operation quickly.

With the continuous availability of critical spare parts suitable for Sundyne, Sammler CS effectively minimizes downtime and guarantees rapid repairs. For operators who depend on high-quality spare parts, Sammler CS offers an unbeatable solution at reasonable prices.

Conclusion: Preventive Maintenance and Efficient Troubleshooting as Keys to Success

In the world of high-performance pumps, there is no room for prolonged downtime. Through preventive and regular maintenance, costly shutdowns can be avoided, and the service life of pumps can be significantly extended. Thanks to its global network and the rapid availability of spare parts, Sammler CS can restore the operation of your equipment as quickly as possible.

With a service offering suitable for Sundyne pumps and compressors, Sammler CS provides the ideal solution for all operators who rely on uninterrupted operation, whether through immediate troubleshooting or preventive maintenance.

Comments